Plastic packaging can be seen everywhere. The plastic film used for vegetable greenhouses is ordinary plastic film, which is relatively thick and not so capricious. We go to the supermarket to buy groceries and use food grade plastic bags. Plastic packaging can be seen everywhere in daily life; When we go to the supermarket to buy beer and drinks, some have a layer of plastic film on the outside. Many of the foods we buy are boxed, such as milk tea, instant noodles, etc., with a thin plastic film on the outside of the box. Are these plastic films the same?

Common heat shrink film materials can be roughly divided into five types: POF, PE, PET, PVC, and OPS. What is the difference between them?

POF film is commonly used in the packaging of some solid foods, usually using a fully sealed packaging method. For example, we can see that instant noodles, milk tea, and cigarettes are all packaged with this material. The full name of POF is multi-layer co extruded polyolefin heat shrink film. The middle layer is made of linear low-density polyethylene (LLDPE), and the inner and outer layers are made of copolymerized polypropylene (PP). It is made by three extruders for plasticization and extrusion, and then processed through special processes such as mold forming and bubble inflation.

The characteristics of PET heat shrink polyester film: stable at room temperature, heat shrink (above glass transition temperature), unidirectional heat shrink more than 70%. The advantages of heat shrink polyester film packaging are: rain resistance, moisture resistance, and mold resistance; Cannot be restored and has certain anti-counterfeiting functions. PET heat shrink polyester film is commonly used in beverages, dairy products, convenience foods, some electronic appliances, metal products, especially in the most important application field of shrink labels.

PVC film has the characteristics of high transparency, good glossiness, and high shrinkage rate;

OPS shrink film (oriented polystyrene) heat shrink film is a new type of OPS heat shrink film packaging material that meets environmental requirements. OPS heat shrink film has the characteristics of high strength, high rigidity, stable shape, good glossiness and transparency. Easy to process, easy to color, good printing performance, and extremely high printing resolution. For trademarks that constantly pursue exquisite printing, it is a qualitative leap. Due to the high shrinkage and strength of OPS film, it can tightly adhere to containers of various shapes. Therefore, it can not only print exquisite patterns, but also meet the needs of various novel packaging containers with different shapes. This non-toxic, odorless, and oil resistant film that meets food hygiene standards allows designers to achieve a 360 ° label design using eye-catching colors.

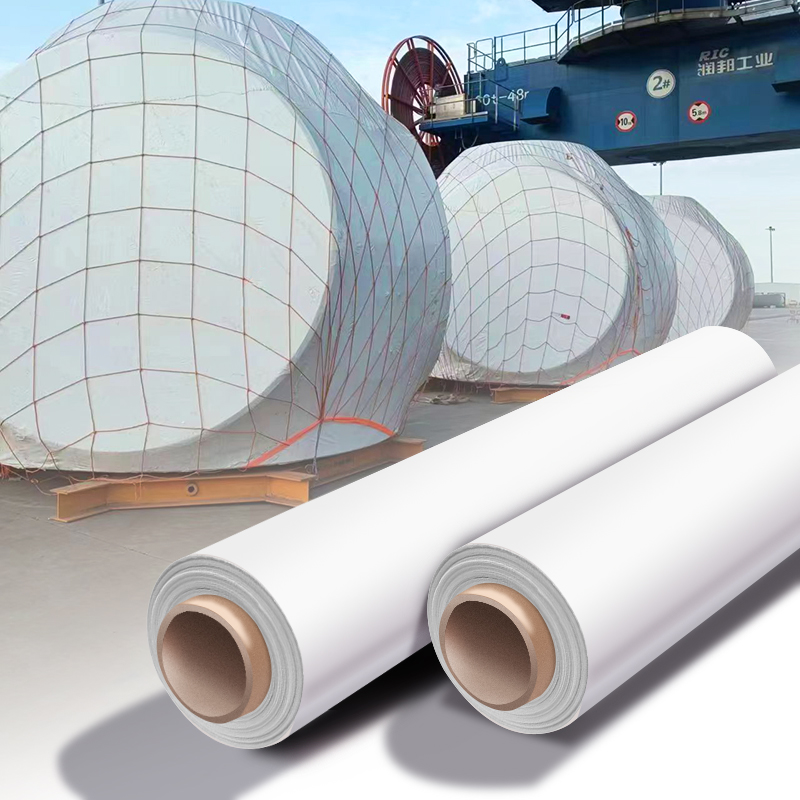

PE heat shrink film is widely used in combination packaging and bundle packaging of liquid foods such as beer, beverages, bottled water, mineral water, seasonings, edible oils, etc, Both ends are cow's eyes;

PE heat shrink film has good flexibility, strong impact resistance, tear resistance, is not easy to break, high shrinkage rate, prevents product scratches, and is easy to transport; Rain proof, moisture-proof, and mold proof; At the same time, advertising can be carried out on PE heat shrink film, which is considerate and transparent, reflects the product image, and can effectively promote product sales;

The application of PE heat shrink film in the liquid food industry, especially in the beverage industry, is a shift in market demand. Heat shrink film is mainly used to replace traditional cardboard packaging. The packaging method of cardboard box+film bag, such as adding paper tray film bag, cardboard film bag, and pure film bag, is becoming more and more widely used;

Because with the rapid development of PET beverage bottles, juice and herbal tea beverages such as Dongpeng Te, Wang Laoji, Uni President, and Coca Cola all use PET beverage bottles and use PE heat shrink film for secondary packaging;

PE heat shrink film belongs to polyester and is an environmentally friendly material. Degradation.

4000538828

4000538828